Robotug is a mobile automatic transport truck (TT), created by British multinational company EMI. This device is able to carry a cargo directly or a set of the trolleys.[1]

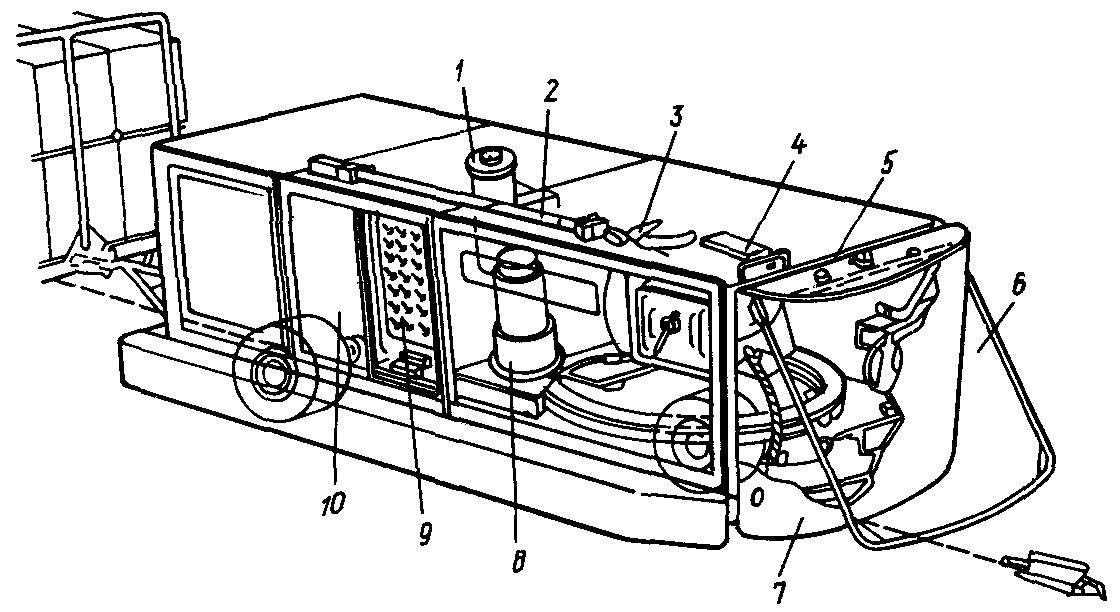

Robotug transport truck with the automatic course stabilization: 1 – brake coil; 2 – transistorized device of control; 3 – handle braking; 4 – drive; 5 – warning lamp; 6 – traffic safety device; 7 – buffer shield; 8 – drive of the control unit; 9 – panel of programming; 10 – battery. [1]

In automatic mode, TT is controlled the electromagnetic field formed by a conductor of AC. Conductor is placed along the route of movement on the floor. Also there is ability of a manual control by driver (in this case, block of the route’s automatic following will be unplugged).[1]

| Specification: [1] | ||

| Payload of truck, t | 1 | |

| Mass of the towing cargo, t | 9 | |

| Speed, km/h | 3.2 | |

| Number of stops on route | 90 | |

| Power from the batteries: | ||

| capacity, A/h | 658 | |

| voltage, V | 24 | |

| Power of the electric traffic motor on route, W | 1693 | |

| Overall dimensions, mm | 2175 x 914 x 692 |

The simplest trajectory of the TT is a closed one-way loop. Multi-path system can contain the intersection points, branches, detours and dead ends. Routes and destination points should be selected in advance by using the switches of on-board device of programming. In case of work according to multi-path system, the whole path will be divided into separate sections. Each section is managed by its external control device. The central computer coordinates the work of the external control devices. A possibility of the simultaneous presence of two TTs within one section is excluded.[1]

References:

1. Козырев Ю. Г. Промышленные роботы: Справочник / Ю. Г. Козырев. — [2-е изд.]. — Москва: Машиностроение, 1988. – 392 с.

2. “ROBOTUGS” SPEED RAIL GOODS – British Pathe. – Mode of access: http://www.britishpathe.com/video/robotugs-speed-rail-goods/query/street.

3. “Robotug” Driverless Truck: Report Number E1-F. – Mode of access: http://legacy.library.ucsf.edu/tid/tbl72a99.

4. THE MECHANICAL HAMBLIN( HIBITION | 13th May 1966 | The Commercial Motor Archive. – Mode of access: http://archive.commercialmotor.com/article/13th-may-1966/86/the-mechanical-hamblin-hibition.

5. 1960 – 2922.PDF. – Mode of access: http://www.flightglobal.com/pdfarchive/view/1960/1960%20-%202922.html.

6. EMI Ltd. AR 1963.pdf. – Mode of access: http://www.kronemyer.com/EMI/EMI%20Ltd.%20AR%201963.pdf.

7. EMI Ltd. AR 1964.pdf. – Mode of access: http://www.kronemyer.com/EMI/EMI%20Ltd.%20AR%201964.pdf.

8. EMI Music AR 1974.pdf. – Mode of access: http://www.kronemyer.com/EMI/EMI%20Music%20AR%201974.pdf.

9. EMI. – Mode of access: http://en.wikipedia.org/wiki/EMI.

In the late 1950s I was working at Rootes Parts, Smallheath, Birmingham. I worked as a planning engineer on the project of setting up the main spares division for The Rootes Group at the old Singer Motors factory on the Coventry Road.

EMI installed a prototype Robotug as an experiment towing the large number of trollies used in selecting motor parts. The equipment worked well having a very simple method of installation.

I was interested to hear of the proposed tram which follows an electronic guidance system and not requiring rails. This has been suggested for Perth WA.

See the item on the website listed as self drive vehicles.